Precision machining

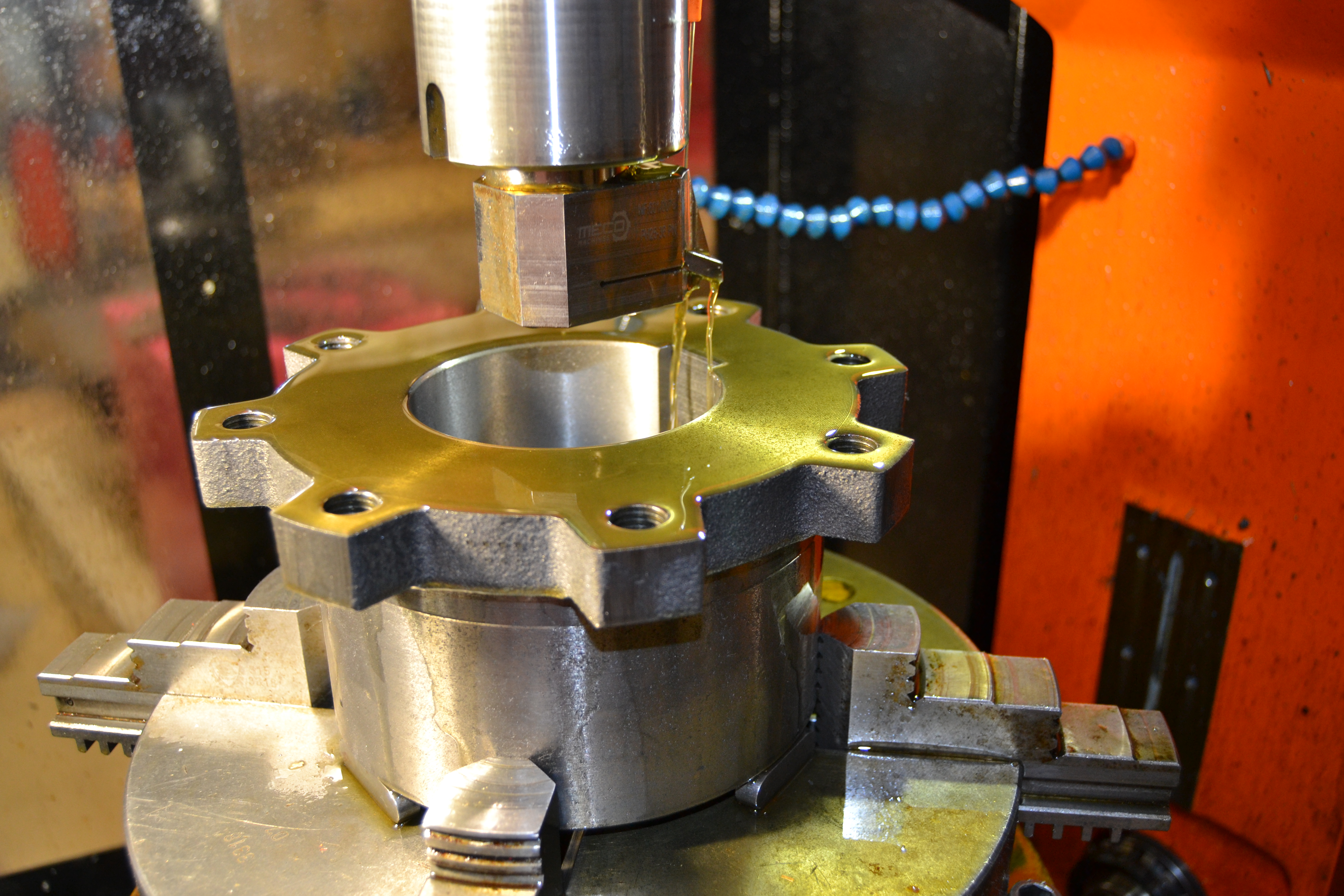

At Hermanos Alfaro we manufacture and repair any kind of parts by precision machining.

We provide with value by complex precision machining that require advanced knowledge and machinery. We repair parts and machinery components through machining on fast delivery terms in order to reduce inactivity time of our client’s equipments.

We work with common materials as aluminum, steel, stainless steel, copper of technical plastics and with materials that require more knowledge as they are titanium, duplex or superduplex.

A versatile production system allow us to machine from prototypes to medium series. Thanks to our CNC lathes, 4 axis lathes and 5 axis machinine centres we can provide any kind of machining in any material.

The most common parts that we machine are:

- Shafts

- Rollers

- Flanges

- Nozzles

- Tappets

- Fittings

- Bolts and nuts

- Pins

- Screw spindles (variable and fix pitch)

- Keyways

- Supports, cases

- Couplings

- Bushings

- Etc.

We provide weleding serices as a complementary activity for machining projects. Homologated procedures and welders that allow us to recover large dimension parts through welding whether they are in steel, stainless steel or aluminum. All pieces that are welded could be subsequent machined, grinded or bushed to achieve a complete recovery in our facilities.

Due to having own technical department we can provide a comprehensive service to our clients by giving them the possibility of manufacturing parts by drawings, samples or inverse engineering, and advising on designing and manufacturing of products.